The healthcare, research and high-tech industries today impose two requirements: purify the air and master the parameters of temperature and relative humidity.

For a long time, this double requirement remained subordinate to heavy equipment implying large-sized technical rooms.

To free themselves from these constraints, and address the increasing demand, an alternative system was developed, far more practical and capable of advantageously replacing traditional installations.

This is our commitment, our dedication, our job.

Gérard BARACHINI

CEO of S.A.S UNITAIR

In 1977, Mr Gérard BARACHINI set up his own company as a fitter of air conditioning installations, the “Etablissements Gérard BARACHINI” orientated towardsoperating theatres in the health-care sector and high-tech industries such as micro-electronics.

These domains require high conditions of air quality with precise parameters for temperature, relative humidity and filtration.

The installations demand large technical rooms to accommodate the necessary machines.

To respond to these demands and address the growing need, an alternative, more practical system, capable of advantageously replacing traditional installations was to appear.

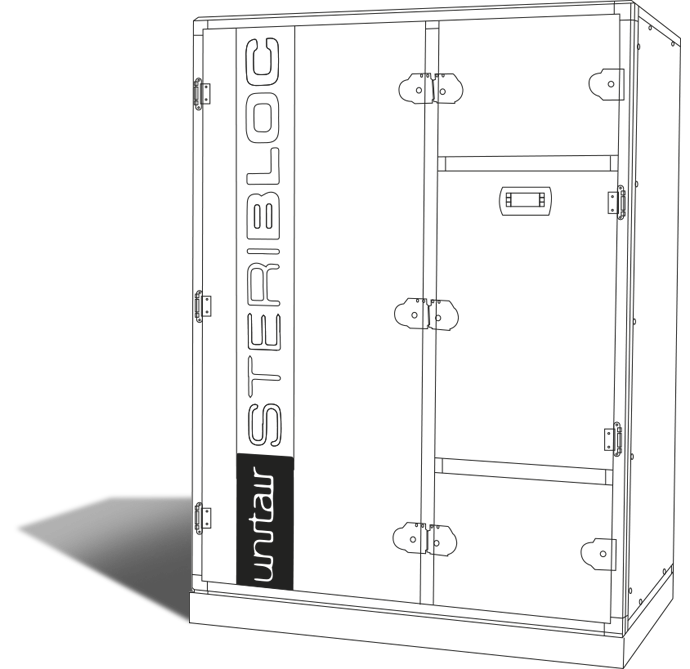

Gérard BARACHINI sat down at his drawing board to study and develop the concept of a self-contained unit, named the STERIBLOC, presented in May 1980.

Simple to install and easy to use, it readily adapted to all types of installation, ensuring permanent monitoring of required conditions of temperature, filtration and pressurization in the treated areas.

Over the following forty years, the STERIBLOC has continued to evolve with regard both to its capacity and its complexity.

In order to better serve his clients, G BARACHIHI then decided to cease his activity as an installer, and in January 1995 created UNITAIR, a company whose principle activity is the design, manufacture and sale of precision air treatment units for the hospital and pharmaceutical sectors and research laboratories.

UNITAIR went on to develop, assemble and distribute five generations of STERIBLOC and widen its range of products, asserting itself on the extremely selective market for air treatment systems.

Thank you for being ever more numerous to show your confidence in our know-how and the quality of our UNITAIR products.

Installer on the industrial market, technically very exacting

1977Birth of the concept of the STERIBLOC, an alternative system, more practical, capable of advantageously replacing traditional installations.

1980Presentation of the STERIBLOC, a self-contained unit ensuring decontamination and permanent monitoring of the required conditions of temperature, relative humidity, filtration and pressurization of the zones treated.

Manufacture and fitting of 1200 STERIBLOC units by the Etablissements Gérard BARACHINI

forCreation of UNITAIRwhose principal activity is the design, manufacture and sale of precision air treatment units for the hospital and pharmaceutical sectors and research laboratories.

19957 generations of STERIBLOC later …

UNITAIR has become a leader on the air treatment market for applications in operating theatres and clean rooms

UNITAIR is first and foremost:

Designing and offering MADE-TO-MEASURE SOLUTIONS for specific applications.

A wide knowledge of customer processes, enabling us to impact the level of quality of the results.

Designed on our production site of over 3000 m², equipped with modern machine tools offering top quality process in manufacture, security and durability.

Our machines are entirely fitted and factory tested before delivery.

To technically assist our customers with the implementation of their projects, the research and development of our machines.

always available all around France and in over 10 other countries, keeping as close as possible to our customers.

of our machines by our own engineers, technical training on how the machines work, for ease and accessibility of operation.

responding to our clients' needs within 24-48 hours, physically or by telephone, thanks to an experienced and competent team of engineers.

Our air treatment systems offer:

We manufacture all our machines in France on our own premises of over 3000m² located in Arles.

UNITAIR and its staff are dedicated to honoring their commitments whilst respecting the applicable standards and current rules and regulations.